Description

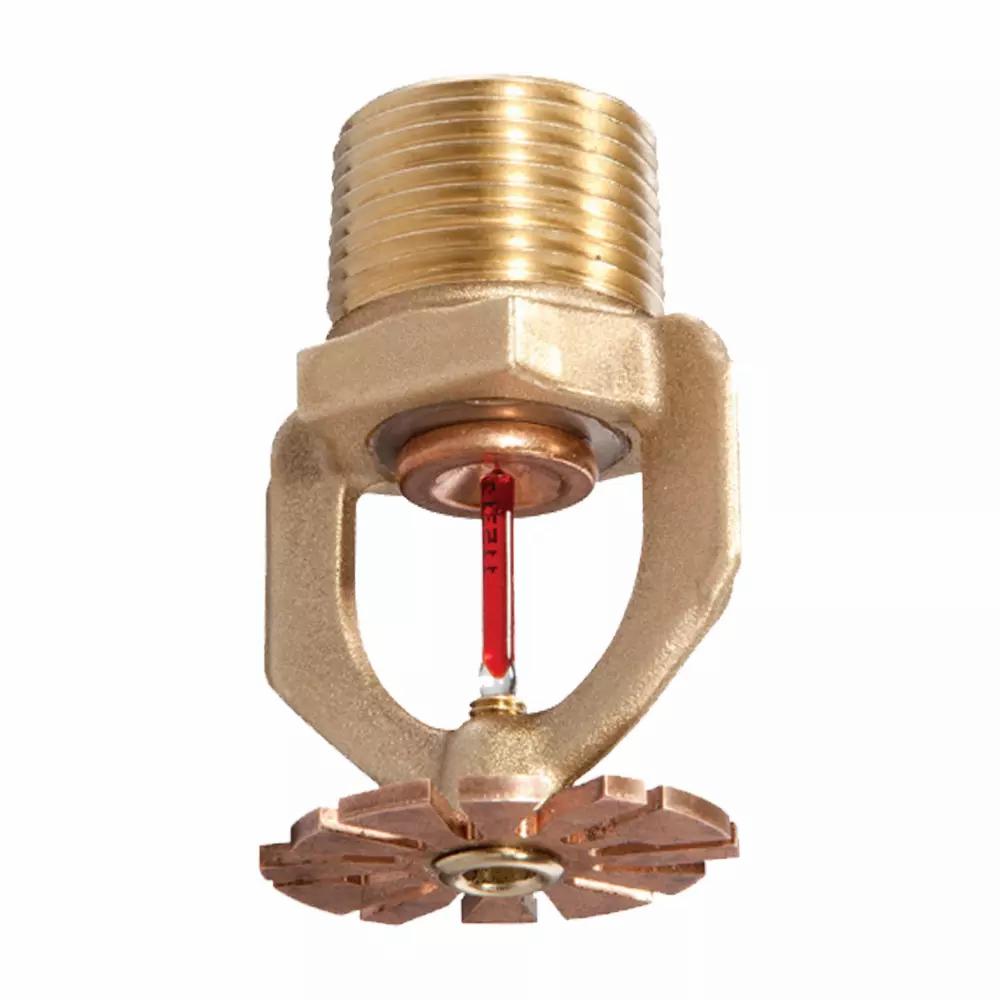

| Model | VK810 |

| Material | Brass |

| Orientation | Sidewall |

| K-factor, gpm/psi ½ (lpm/bar ½ ) | 14.0 (202) |

| Maximum Working Pressure | 175 psi (12 bar) |

| Temperature Rating °F (°C)1 | 155°F (68°C)-200°F (93°C) |

| Thread Size | 3/4″ NPT (20 mm) |

+86 13901803146

The E-Type 3D nozzle is an open nozzle designed for directional spray applications in fixed fire protection systems. The nozzle is an open design (non-automatic) with an external deflector that produces a steady, uniform cone spray of low to medium velocity droplets. The E-Type nozzle is available in a variety of orifice sizes and spray angles to suit the design application and is available with ½” NPT (DN15) external pipe threads. The nozzle base material is brass and the entire assembly can be electroless nickel plated for applications requiring corrosion resistance.

| Model | VK810 |

| Material | Brass |

| Orientation | Sidewall |

| K-factor, gpm/psi ½ (lpm/bar ½ ) | 14.0 (202) |

| Maximum Working Pressure | 175 psi (12 bar) |

| Temperature Rating °F (°C)1 | 155°F (68°C)-200°F (93°C) |

| Thread Size | 3/4″ NPT (20 mm) |

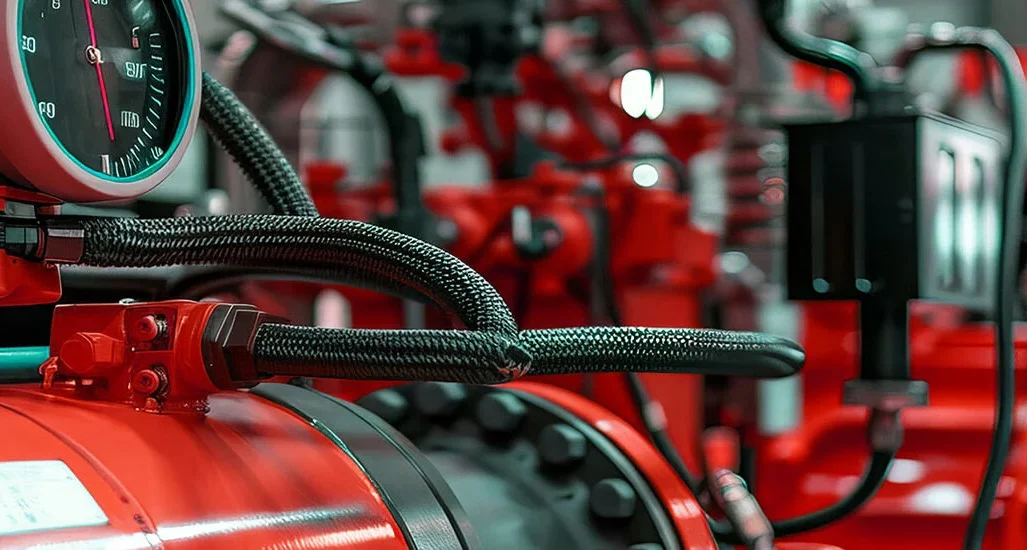

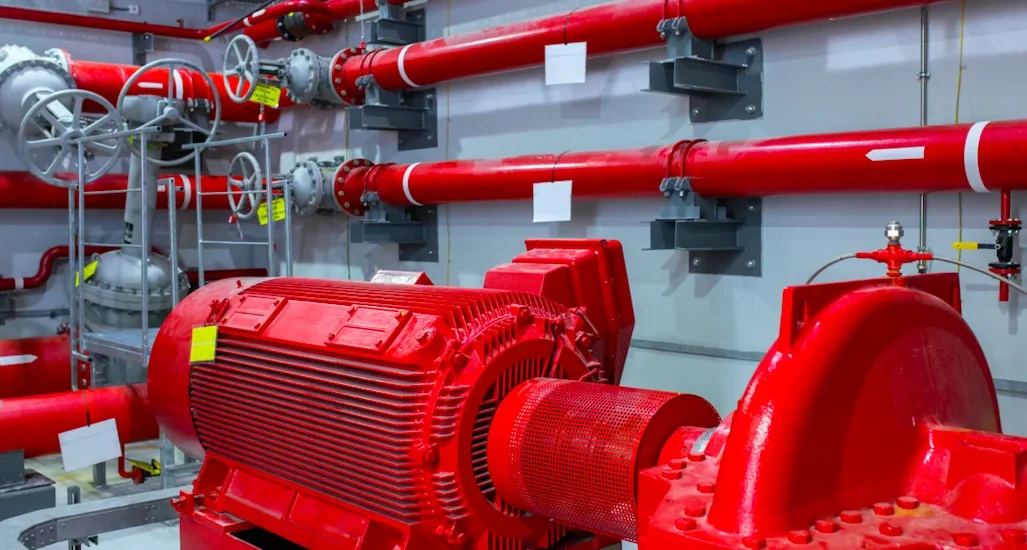

From soaring commercial towers and industrial plants to vital municipal projects and residential complexes, our firefighting valves provide unmatched reliability where safety matters most. Designed to perform under pressure, they safeguard lives and assets across diverse environments—ensuring your fire protection system is always ready when it counts.

We deliver reliable firefighting valves with advanced manufacturing, strict testing, and global standards—backed by fast delivery and expert support.

A1: Our products meet ISO, UL, FM, CE and other international certifications to satisfy different market and project requirements.

A2: Yes, we offer customization in size, pressure rating, connection type, and surface treatment to meet specific application needs.

A3: Standard models can usually be shipped within 7–15 days. Bulk or customized orders will require confirmation of the exact lead time.

A4: We implement strict raw material inspection, process control, and final product testing, backed by warranty and after-sales support.